Familles agricoles

Familles agricoles

Contenu en vedette

Les grands et les petits moments qui rythment la vie agricole et la ferme, les innovations ingénieuses d’agricultrices et d’agriculteurs, les défis traversés avec résilience ou les succès remportés avec passion : c’est à travers les reportages de ferme et les portraits de relève agricole que se racontent les histoires quotidiennes et humaines de l’agriculture.

Unissez un agriculteur, un plombier et une comptable et vous aurez toute une équipe agricole. Bienvenue à la Ferme de Ste-Victoire, à Ste-Victoire!

Oui, Patrick de la Ferme M.B. Pelletier allait joindre la ferme, mais il a d’abord exploré de nouvelles idées pendant 10 ans comme expert-conseil.

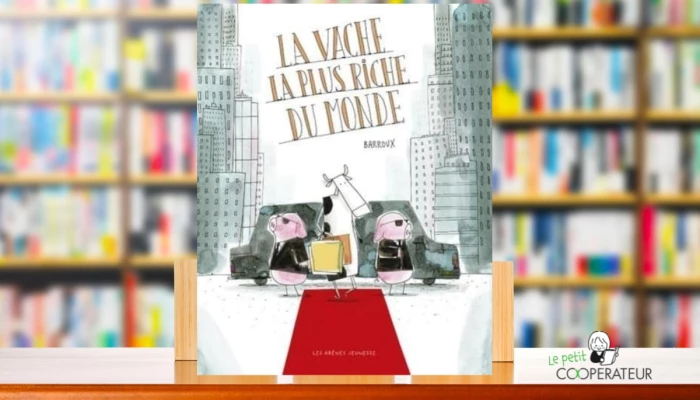

La chronique Le petit Coopérateur vous présente une vache au grand potentiel économique, mais aux rêves doux.

La ferme s’appelle « Laitue St-Jacques ». La laitue? C’est sa spécialité. Le nom St-Jacques? Connu de New York à Boston, de Toronto à Chicago!

Samuel Lanctôt a gagné le gros lot : un quota de 6000 poules pondeuses. En sus du concours : une conjointe et une famille avec qui partager le projet!